In today's rapidly evolving manufacturing landscape, the integration of advanced technologies is essential for optimizing productivity and maintaining competitive advantage. The Combination Weighing Machine has emerged as a pivotal innovation, significantly enhancing the efficiency and precision of production processes across various industries. According to a report by Market Research Future, the global market for weighing equipment is projected to grow at a CAGR of 4.5%, driven by the increasing demand for accuracy and speed in product measurement. This revolutionary technology not only minimizes waste and reduces labor costs, but it also plays a critical role in meeting the stringent quality standards of modern manufacturing. As companies strive to unlock higher operational efficiencies, the Combination Weighing Machine stands out as a key asset, poised to redefine the future of manufacturing practices.

Combination weighing machines have emerged as a game changer in modern manufacturing processes, offering a myriad of benefits that enhance efficiency and precision. According to a recent report by Grand View Research, the global market for multihead weighers is projected to reach $1.2 billion by 2027, indicating a significant adoption of these machines across industries. By integrating advanced technologies, combination weighing machines can optimize the weighing process, reducing cycle times and minimizing material waste. This not only boosts productivity but also enhances overall product quality, which is paramount in competitive markets.

One key advantage of combination weighing machines is their ability to automate the weighing process, allowing manufacturers to streamline operations and allocate human resources more effectively. A study from Research and Markets shows that automation in manufacturing could contribute to a 20% increase in production efficiency. By implementing these machines, manufacturers can achieve consistency in measurements, leading to a reduction in errors and rework.

Tip: Regular maintenance of combination weighing machines is essential for ensuring consistent performance. Schedule routine inspections to prevent unexpected breakdowns and maintain optimal accuracy. Additionally, training staff on operating these machines can significantly reduce the learning curve and improve overall productivity.

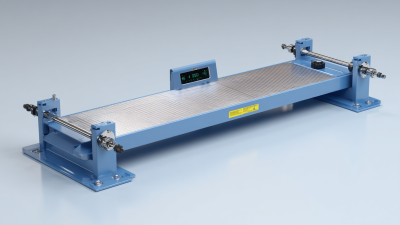

In modern manufacturing, the pursuit of accuracy and consistency is paramount for ensuring product quality and minimizing waste. Combination weighing machines have emerged as a game-changing technology in this endeavor. By utilizing multiple load cells and advanced algorithms, these machines deliver precise weight measurements that significantly enhance the reliability of production processes. This ability to achieve fine-tuned accuracy is vital in industries such as food processing, pharmaceuticals, and chemicals, where even minor discrepancies can lead to costly errors and compromised safety.

Moreover, the implementation of combination weighing machines facilitates a more streamlined and efficient workflow. Traditional weighing methods often involve tedious manual processes that can introduce variability and errors. In contrast, combination weighing systems automate these processes, ensuring consistent outcomes every time. Their ability to quickly and accurately blend ingredients or components not only boosts productivity but also maintains stringent quality control standards. As manufacturing continues to evolve, the integration of such advanced technologies will be essential in maintaining competitive edge while meeting the growing demand for precision in today’s market.

In modern manufacturing, combination weighing machines have become indispensable tools that enhance efficiency and precision in various processes. When selecting a combination weighing machine, several key features stand out as essential for maximizing productivity. First and foremost, look for machines equipped with high-speed processing capabilities. These advanced systems can quickly analyze weight measurements and streamline the weighing process, enabling faster throughput which is critical in high-volume production environments.

Another significant feature to consider is the precision of the weighing mechanism. Machines that utilize advanced load cell technology generally offer enhanced accuracy, which is crucial for industries where even minor discrepancies can lead to substantial financial losses. Additionally, user-friendly interfaces that allow seamless operation and easy integration with existing systems can greatly improve workflow and reduce the learning curve for new operators.

Finally, robust software support for data collection and analysis can help manufacturers track performance metrics and improve their overall process efficiency, making these machines vital assets in the quest for operational excellence.

Combination weighing machines have revolutionized the manufacturing landscape across various industries, enhancing operational efficiency and precision. These advanced systems utilize multiple load cells to simultaneously weigh different components, allowing manufacturers to achieve greater accuracy in their production processes. According to a report by MarketsandMarkets, the global market for combination weighing machines is projected to reach $620 million by 2025, driven by the increasing demand for automation and precise weighing in industries such as food and beverage, pharmaceuticals, and packaging.

In the food and beverage sector, combination weighing machines play a crucial role in ensuring product consistency and quality. For instance, in snack food production, these systems can accurately weigh and mix various ingredients, significantly reducing the chances of errors in product formulation. A study conducted by Research and Markets indicated that the integration of combination weighers in food processing can improve throughput by up to 30%, enabling manufacturers to meet stringent regulatory standards while optimizing their operations.

Similarly, in the pharmaceutical industry, precision is paramount. Combination weighing machines help in the accurate dosing of active ingredients, ensuring that each product meets exact specifications and compliance regulations. The International Society for Pharmaceutical Engineering reports that the use of these machines has led to a 20% reduction in waste through improved accuracy, which not only saves costs but also supports sustainability efforts by minimizing excess material use in production. This versatility and efficiency underline the pivotal role of combination weighing machines in modern manufacturing practices.

The landscape of modern manufacturing is evolving rapidly, and combination weighing machines are at the forefront of this transformation. With increasing demands for efficiency and precision, manufacturers are turning to advanced combination weighing technologies. These machines, which utilize multiple load cells to weigh products simultaneously, offer unparalleled accuracy and speed, thus minimizing waste and optimizing production lines. As industries strive for leaner operations, the integration of combination weighing systems is becoming indispensable for maintaining competitiveness in a market that is continually pushing for higher quality standards and reduced lead times.

Looking ahead, the future trends in combination weighing technology promise even greater advancements. Innovations such as artificial intelligence and machine learning are being integrated into weighing systems, allowing for real-time data analytics and predictive maintenance. This not only enhances operational efficiency but also contributes to smarter supply chain management. Additionally, the development of more compact and versatile machines caters to the needs of diverse industries, from food production to pharmaceuticals. As manufacturers increasingly rely on automation, the evolution of combination weighing technology will play a critical role in shaping the future of production efficiency, leading to more streamlined processes and better resource management.