In the ever-evolving world of manufacturing, the Rotary Collecting Table Machine has become a pivotal tool for enhancing efficiency and streamlining production processes. According to industry expert Dr. Emily Fischer, "A properly utilized Rotary Collecting Table Machine can dramatically reduce cycle times and improve overall workflow." Her insights underscore the importance of mastering the nuances of this essential equipment.

As manufacturers seek ways to optimize their operations, understanding how to use a Rotary Collecting Table Machine effectively is crucial. With the right techniques, operators can maximize the machine’s capabilities, ensuring precision and consistency in the final product. This article will explore ten essential tips that can help both new and experienced users harness the full potential of this invaluable machinery, ultimately leading to enhanced productivity and reduced operational costs.

By implementing these strategies, manufacturers can not only increase their output but also maintain high-quality standards. Whether you're just beginning to work with a Rotary Collecting Table Machine or looking to refine your existing skills, these tips will provide a solid foundation for achieving excellence in your operational practices.

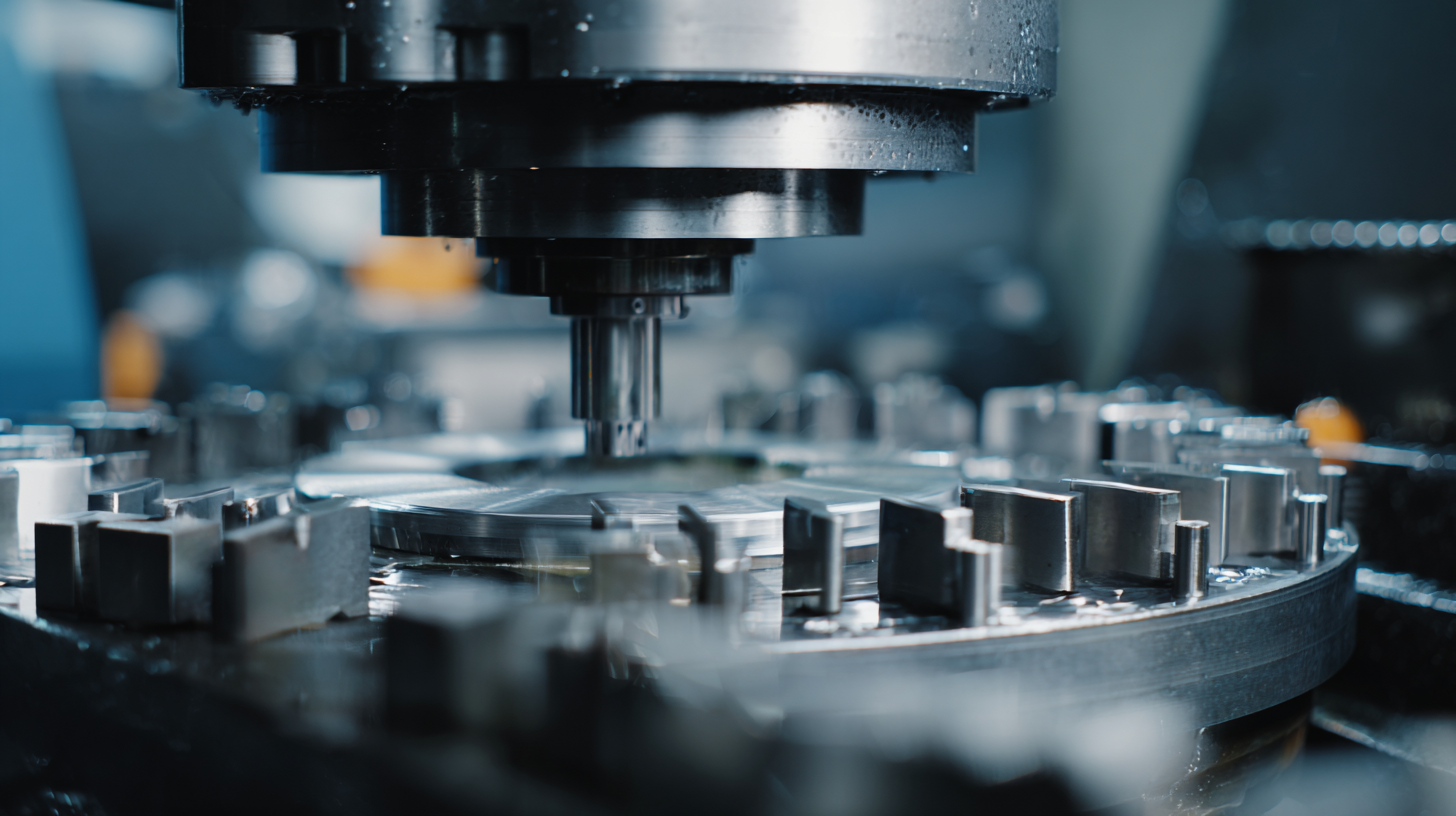

Rotary collecting table machines are essential in various industries for their efficiency and versatility in handling materials. Understanding the fundamentals of how these machines operate can significantly enhance productivity. A rotary collecting table functions by rotating a platform, allowing for seamless transfer and organization of parts throughout the manufacturing process. According to a report by Industry Research, the adoption of rotary collecting systems can lead to a 30% increase in operational efficiency by minimizing downtime and maximizing workflow fluidity.

To effectively utilize a rotary collecting table machine, it's crucial to grasp its components and functionalities. Typically equipped with adjustable speed settings and customizable table sizes, these machines offer flexibility tailored to specific operational needs. Recent survey data from Manufacturing Today indicates that 65% of manufacturers who implement advanced rotary systems experience a notable reduction in assembly line errors. By investing time in training personnel on these machines, companies can unlock their full potential and optimize their production lines, ensuring higher quality output and reduced waste.

When choosing a rotary collecting table machine, several key features can significantly enhance its effectiveness. First, the build quality and material of the machine should be examined. Opt for a model made of durable materials that can withstand heavy usage, ensuring longevity and consistent performance. Additionally, adjustable speed settings are essential, allowing users to tailor the machine's operation to different production requirements, thus increasing efficiency.

Another crucial feature to consider is the size and design of the collecting area. A spacious and well-designed collection area facilitates better sorting and organizing of collected items, which can mitigate workflow interruptions. Moreover, features such as easy-clean surfaces and modular designs can greatly contribute to reducing downtime and improving maintenance. Lastly, safe operation features, including emergency stops and safety guards, are vital for ensuring operator safety while using the rotary collecting table. These elements combined will lead to a more productive and reliable working environment.

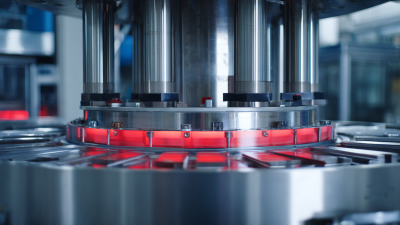

When utilizing a rotary collecting table machine, proper setup and positioning techniques are crucial for enhancing efficiency and productivity. A well-optimized machine setup can significantly affect operation speed and accuracy. According to industry reports, ensuring the machine is situated on a stable surface can reduce vibrations by up to 30%, leading to improved performance and longevity. Additionally, aligning the machine with respect to workflow can minimize unnecessary handling, which studies show can enhance overall processing time by as much as 25%.

Proper ergonomic positioning also plays a vital role in maximizing operator effectiveness. Research from leading industrial efficiency studies indicates that positioning the machine at an optimal height prevents strain and fatigue, allowing operators to maintain focus over longer periods. This adjustment can reduce workplace injuries and increase productivity by up to 15%. Furthermore, keeping essential tools and materials within arm's reach can streamline processes, thus minimizing downtime and ensuring that tasks are completed efficiently and effectively.

Proper maintenance of a rotary collecting table machine is crucial for maximizing its lifespan and efficiency. According to industry reports, regular maintenance can extend the operational life of such machines by up to 30%. Key maintenance practices include routine cleaning, lubrication of moving parts, and timely replacement of worn components. For instance, ensuring that the drive belts are in good condition can prevent unexpected breakdowns, which, as noted by Machinery World, can lead to production delays costing manufacturers thousands of dollars in lost productivity.

In addition, monitoring the machine's performance through periodic inspections can help identify potential issues before they escalate into major repairs. The Institute of Manufacturing Technology suggests implementing a maintenance schedule that includes checks on bearings, electrical systems, and software updates. By adhering to these maintenance tips, operators can not only achieve better performance but also significantly reduce repair costs, aligning with the data that highlights the average savings of 20% on maintenance expenses when proactive measures are taken. This strategic approach not only benefits the machine's efficiency but also enhances overall production output.

When operating a rotary collecting table machine, safety should be your top priority. Before starting the machine, always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and slip-resistant footwear. Ensure that your workspace is clean and free of any obstacles that could interfere with the machine's operation. Additionally, familiarize yourself with the machine's controls, emergency stops, and potential hazards to minimize the risk of accidents.

During operation, maintain a safe distance from the rotating parts and be aware of your surroundings. It's crucial to keep hands and loose clothing away from the machine's moving components to prevent entanglement. Regularly inspect the table for any signs of wear or malfunction, and address any issues promptly. Implementing these best practices not only enhances safety but also promotes a smoother and more efficient operation of the rotary table.