In today's fast-paced manufacturing environment, efficiency and accuracy are paramount for sustaining competitive advantage. One of the key innovations driving this evolution is the implementation of Checkweigher Online solutions. These advanced systems effectively integrate digital technology into production lines, significantly enhancing the precision of weight measurements. By automating the weighing process, manufacturers can achieve accuracy rates of up to 99%, minimizing errors and reducing waste. This remarkable improvement not only streamlines operations but also ensures compliance with regulatory standards, ultimately resulting in higher product quality and customer satisfaction. As businesses seek to maximize efficiency while maintaining stringent quality controls, Checkweigher Online technologies stand out as a critical component in the pursuit of operational excellence.

Implementing online checkweigher solutions in production lines offers a multitude of advantages that contribute significantly to enhancing operational efficiency. One of the primary benefits is the ability to achieve an incredible accuracy rate of up to 99%. This level of precision minimizes product waste and reduces the likelihood of costly errors in packaging, ensuring that companies maintain high standards and compliance with regulations.

Moreover, online checkweighers facilitate real-time monitoring of weight data, allowing manufacturers to promptly address discrepancies without disrupting the production flow. This streamlined approach not only saves time but also empowers operators to make informed decisions based on live data, leading to better resource allocation and improved overall productivity. By incorporating these advanced solutions, production lines can significantly enhance quality control processes and foster continuous improvement, ultimately contributing to a more resilient and competitive business model.

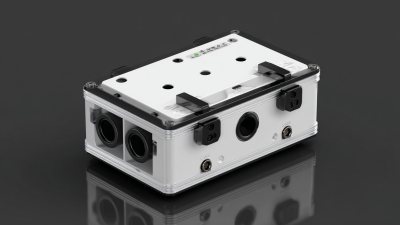

In modern production lines, the accuracy of checkweighers is crucial for minimizing product waste and optimizing cost efficiency. Recent advancements in checkweigher technology have demonstrated significant improvements, with some systems achieving accuracy rates of up to 99%. This level of precision directly impacts the reduction of product giveaway, ensuring that manufacturers do not overfill, which can lead to unnecessary expenses. By implementing advanced inspection systems that include both metal detection and checkweighing functionality, companies can streamline their operations while enhancing the integrity of their products.

The integration of checkweighers into production lines also addresses growing concerns around food safety and contamination. As manufacturers strive to meet diverse consumer demands while ensuring compliance with safety standards, precise weight control becomes a pivotal aspect of production efficiency. The latest innovations, such as combination systems, not only save space on the production floor but also provide a more comprehensive inspection process, thereby reducing the risk of errors. By adopting these cutting-edge solutions, companies are better positioned to achieve their sustainability goals while maximizing profitability through significant cost savings and reduced waste.

| Production Line | Checkweigher Accuracy (%) | Product Waste Reduction (%) | Cost Savings ($) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Beverage Manufacturing | 99 | 15 | 20000 | 4 |

| Snack Food Production | 98.5 | 12 | 15000 | 3 |

| Dairy Production | 97 | 8 | 10000 | 5 |

| Pharmaceuticals | 99.2 | 10 | 25000 | 6 |

| Bakery Products | 98 | 9 | 12000 | 4 |

Recent advancements in checkweighing technology have led industries to achieve unprecedented accuracy levels, with modern systems reporting up to 99% precision in production lines. For instance, in the food processing sector, companies employing online checkweighers have noted a significant reduction in product giveaways. The Food Industry Best Practices introduced in 2022 highlight that the integration of automatic checkweighing systems has minimized over-packaging by 3.5%, translating into substantial cost savings for manufacturers.

Additionally, pharmaceuticals have seen remarkable improvements in product consistency and compliance. A case study from the Pharmaceutical Manufacturing Association revealed that integrating checkweighers into production lines reduced the margin of error on dosage weights to less than 0.5%. This leap in precision not only ensures regulatory compliance but also enhances consumer trust in product safety. As industries increasingly adopt automated solutions, the continuous monitoring provided by modern checkweighers has joined quality control processes, providing real-time data that drives operational excellence and product integrity.

In the competitive landscape of manufacturing, technological innovations are crucial for optimizing production processes. Checkweigher solutions have seen significant advancements, increasing their accuracy to unprecedented levels. These modern systems are equipped with sophisticated software that enhances device management and operational efficiency, enabling manufacturers to ensure consistent product safety and quality. For instance, the latest software upgrades facilitate enhanced data insights, allowing food manufacturers to maintain compliance with safety standards while optimizing their production lines.

Moreover, events like ProPak Africa 2025 highlight the continued evolution of industrial weighing and inspection technologies. Companies are showcasing their latest offerings, demonstrating how precision checkweighers can adapt to various industry needs, particularly in sectors like pharmaceuticals where brand protection is paramount. The integration of state-of-the-art checkweighers into production lines not only enhances accuracy but also streamlines operations, ultimately driving productivity and reducing waste. As these innovations take center stage, manufacturers are poised to reap the benefits of greater efficiency and reliability in their processes.

This chart illustrates the accuracy improvements achieved by implementing online checkweigher solutions in manufacturing production lines. The data showcases the accuracy percentage measured over a period of six months, highlighting the effectiveness of technological innovations.

Checkweighers play a crucial role in maintaining regulatory compliance in production lines, especially in the pharmaceutical industry. As quality standards become increasingly stringent, manufacturers are tasked with ensuring their products meet specific weight specifications. Checkweighers help achieve this by providing real-time monitoring of product weight, enabling producers to detect underweight or overweight items immediately. This not only enhances accuracy but also minimizes waste, ultimately contributing to both product quality and compliance with regulatory requirements.

Additionally, the integration of advanced checkweigher online solutions has transformed the quality assurance process. By achieving accuracy levels of up to 99%, these systems ensure that every item produced adheres to set weight limits. This accuracy is indispensable for avoiding costly penalties associated with non-compliance and ensuring consumer safety. Furthermore, the data collected from checkweighers can inform adjustments in the production process, leading to continuous improvements and greater overall efficiency in manufacturing operations.