In the ever-evolving landscape of manufacturing, the pursuit of efficiency is paramount. As businesses strive to streamline operations, technologies like the Rotary Collecting Table Machine are emerging as game-changers. According to a report by Allied Market Research, the global manufacturing automation market is expected to reach $214 billion by 2025, highlighting the critical role of innovative machinery in enhancing productivity. The Rotary Collecting Table Machine not only facilitates the seamless transfer of components but also minimizes labor costs and waste, contributing to a more sustainable production process. As manufacturers continue to seek solutions that optimize workflow and increase throughput, the benefits of incorporating sophisticated machinery like the Rotary Collecting Table Machine cannot be overlooked. This technology is not just a trend; it represents a foundational shift towards smarter, more effective manufacturing practices.

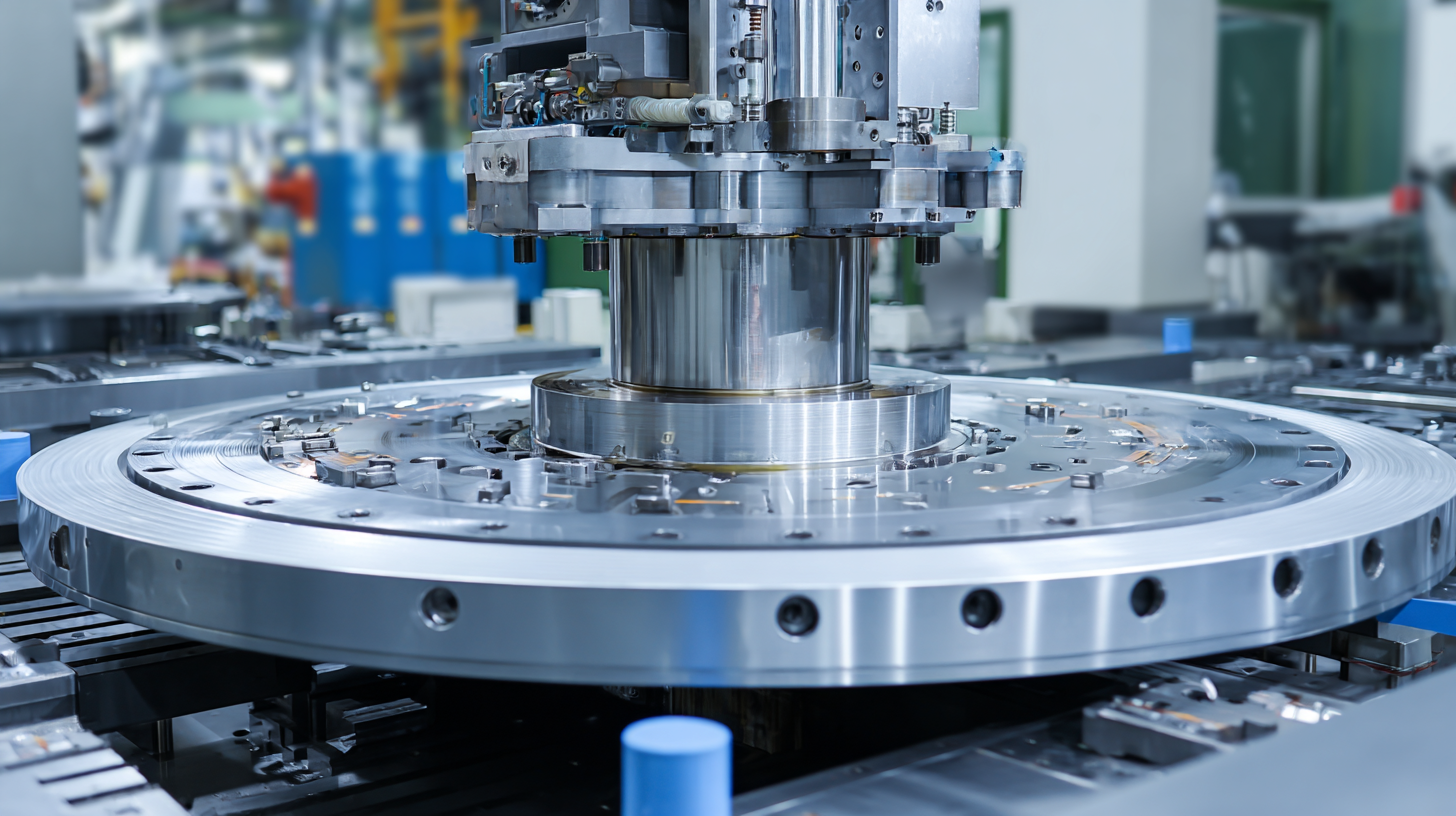

Rotary collecting table machines represent a significant advancement in manufacturing efficiency, seamlessly integrating mechanics that optimize production workflows. At the heart of these machines lies a circular platform equipped with multiple collection points, which allows for the swift gathering of products from various assembly lines. This design minimizes bottlenecks, as items can be continuously fed onto the table, enabling workers to maintain a steady pace without interruptions.

The rotation mechanism ensures that products are efficiently repositioned and delivered to the next stage of production or packaging, ultimately reducing idle time and increasing throughput.

Rotary collecting table machines represent a significant advancement in manufacturing efficiency, seamlessly integrating mechanics that optimize production workflows. At the heart of these machines lies a circular platform equipped with multiple collection points, which allows for the swift gathering of products from various assembly lines. This design minimizes bottlenecks, as items can be continuously fed onto the table, enabling workers to maintain a steady pace without interruptions.

The rotation mechanism ensures that products are efficiently repositioned and delivered to the next stage of production or packaging, ultimately reducing idle time and increasing throughput.

The operation of rotary collecting table machines is characterized by their synchronized movement and precise engineering. Each segment of the table can be tailored to accommodate different product sizes and shapes, enabling manufacturers to adapt quickly to changing production demands. Additionally, advanced technology enhances their functionality, including sensors that monitor product flow and automated adjustments in speed to maintain optimal operational efficiency. This adaptability not only streamlines processes but also enhances overall product quality, making rotary collecting tables indispensable in modern manufacturing settings.

The implementation of rotary collecting table machines in manufacturing has demonstrated substantial efficiency gains, significantly reducing production time across various industries. By streamlining the handling and positioning of materials, these machines facilitate quicker transitions between production phases. For instance, data from multiple manufacturing sectors indicate an average reduction in cycle time by approximately 20-30%, primarily attributed to the machines' ability to automatically collect and distribute items in real-time. This process minimizes manual intervention, thereby decreasing the likelihood of human error and enhancing operational precision.

Furthermore, industry analyses reveal that companies utilizing rotary collecting tables not only experience faster production rates but also achieve higher overall throughput. By optimizing the workflow, these machines enable manufacturers to handle larger volumes of products without compromising quality. In essence, the integration of rotary collecting tables serves as a transformative solution, allowing businesses to meet increasing market demands while efficiently managing resources. Through quantifiable metrics, it is clear that the adoption of this technology leads to more sustainable industrial practices and a competitive edge in the marketplace.

| Parameter | Before Implementation | After Implementation | Efficiency Gain (%) |

|---|---|---|---|

| Production Time per Cycle (min) | 30 | 20 | 33.33 |

| Total Production Output (units per hour) | 120 | 180 | 50.00 |

| Downtime per Shift (min) | 45 | 15 | 66.67 |

| Labor Hours per Unit | 2.5 | 1.5 | 40.00 |

| Overall Equipment Effectiveness (OEE %) | 60 | 85 | 41.67 |

The adoption of rotary collecting table machines in manufacturing settings has demonstrated significant cost-effectiveness, transforming the way businesses analyze their return on investment (ROI). These machines streamline operations by facilitating continuous movement of products between processes, reducing idle time and enhancing workflow. By minimizing manual handling and optimizing transition periods, companies can realize substantial savings in labor costs and operational inefficiencies.

Moreover, the longevity and durability of rotary collecting table machines contribute to their overall cost-effectiveness. Their reliable performance leads to fewer breakdowns and lower maintenance costs, which can further enhance a company's bottom line. Manufacturers increasingly view these machines not just as an initial investment but as a strategic asset that pays dividends through improved productivity and reduced operational disruption. As businesses continue to modernize their production lines, the ROI on these machines becomes increasingly favorable, highlighting the importance of integrating innovative technology into manufacturing processes.

The adoption of rotary collecting table machines is transforming efficiencies across various manufacturing sectors by enhancing operational flexibility and customization. These machines enable industries to tailor their processes to meet specific production demands, ensuring a seamless integration with existing workflows. As production becomes increasingly diverse, the ability to quickly reconfigure machinery to accommodate different products is crucial. This flexibility not only shortens lead times but also reduces waste, leading to a more sustainable manufacturing environment.

In line with emerging technologies, such as hybrid VTOL drones, rotary collecting machines exemplify the shift towards sector-specific applications, addressing unique operational challenges with innovative solutions. The customizable nature of rotary collecting technology allows manufacturers to adapt easily to evolving market trends and consumer preferences, fostering a culture of continuous improvement. This evolution is crucial in a landscape where efficiency and agility are paramount, demonstrating the vital role that these advanced machines play in revolutionizing manufacturing processes.

In today's fast-paced manufacturing environment, minimizing waste and errors is crucial for operational success.

Rotary collecting tables play a significant role in optimizing material handling processes, thereby enhancing overall efficiency.

These machines streamline the flow of materials, allowing for seamless transitions between various stages of production.

By efficiently collecting and distributing components, rotary tables minimize the time spent on handling and assembly, which significantly reduces the likelihood of errors and waste generation.

Rotary collecting tables play a significant role in optimizing material handling processes, thereby enhancing overall efficiency.

These machines streamline the flow of materials, allowing for seamless transitions between various stages of production.

By efficiently collecting and distributing components, rotary tables minimize the time spent on handling and assembly, which significantly reduces the likelihood of errors and waste generation.

Moreover, rotary collecting tables enhance precision in material placement. With their ability to automate the collection and sorting of items, manufacturers can maintain tighter control over inventory and reduce the chances of misplacement.

This heightened accuracy not only cuts down on material waste but also improves production timelines, as components are aligned and ready for the next phase of manufacturing without unnecessary delays.

As businesses seek innovative solutions to elevate productivity, the integration of rotary collecting tables emerges as a transformative approach to achieving greater efficiency and reliability in manufacturing processes.