The poultry industry is undergoing a significant transformation, driven by advancements in technology that aim to enhance efficiency and precision in processing. At the forefront of this revolution is the Chicken Sorting Machine, a pivotal tool designed to streamline the sorting and grading of chickens based on weight, size, and quality. This innovative machinery not only accelerates the process but also minimizes human error, ensuring a higher standard of quality control in poultry products. In this article, we will explore the functionalities, benefits, and future potential of Chicken Sorting Machines, illuminating how they are reshaping the landscape of poultry processing. By understanding the operational mechanics and impacts of these machines, stakeholders within the industry can better navigate the challenges of modern poultry production while optimizing their output and profitability.

The poultry industry is witnessing a significant transformation driven by the need for advanced chicken sorting machines. As consumer preferences shift towards higher quality and more sustainably sourced meat, processors are under increasing pressure to enhance efficiency and precision in their operations. Traditional sorting methods are often labor-intensive and prone to error, resulting in inconsistent product quality and wasted resources.

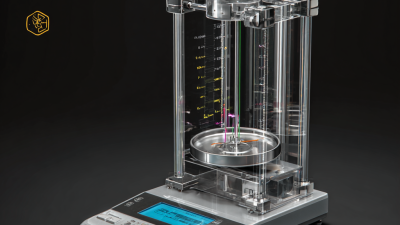

Advanced sorting technology addresses these challenges by utilizing artificial intelligence and advanced imaging systems that can assess multiple attributes of chicken products, including size, weight, and quality, with high accuracy.

Advanced sorting technology addresses these challenges by utilizing artificial intelligence and advanced imaging systems that can assess multiple attributes of chicken products, including size, weight, and quality, with high accuracy.

Moreover, the integration of automated sorting machines boosts overall operational efficiency. By reducing the reliance on manual labor, processors can minimize the risk of contamination and enhance workplace safety. Additionally, these machines can operate at high speeds, ensuring that the sorting process keeps pace with modern production demands. The investment in advanced chicken sorting technologies not only streamlines processing workflows but also aligns with the industry's broader goal of sustainability by reducing waste and optimizing resource use. As the poultry sector continues to evolve, the adoption of these innovative solutions will be crucial in meeting both market and consumer expectations.

The poultry processing industry is witnessing a significant transformation driven by advanced technologies that enhance efficiency and sustainability. Key innovations, such as the integration of artificial intelligence (AI) and smart robotics, have allowed meat processors to move beyond outdated electromechanical systems. According to a recent industry report, the global chicken meat market is projected to grow significantly, with AI-driven monitoring systems optimizing farming practices, thereby improving production efficiency while minimizing waste.

Moreover, the advent of PoulTrans—a cutting-edge image captioning framework utilizing Convolutional Neural Networks integrated with transformer models—marks a pivotal shift in poultry condition assessment. This technology plays a crucial role in improving welfare assessments in large-scale farms, which can house up to 50,000 birds. As traditional methods struggle to keep pace with such operations, PoulTrans provides precise, real-time data that enhances decision-making in poultry management. Furthermore, as the industry leans towards sustainability, converting chicken waste into organic fertilizers not only improves soil health but also benefits smallholder farmers, contributing to a more circular economy in poultry processing.

| Technology | Description | Benefits | Implementation Stage |

|---|---|---|---|

| AI Sorting Systems | Automated systems that use image recognition and artificial intelligence to sort chickens based on size and quality. | Increased accuracy in sorting, reduced labor costs, and improved product quality. | Early Adoption |

| Laser Scanning | Use of laser technology to measure the dimensions of chickens for precise grading. | Enhanced speed and precision in sorting, leading to improved efficiency. | Mainstream |

| Machine Learning Analytics | Analysis of data from sorting processes to optimize performance and reduce waste. | Data-driven insights leading to continuous improvement in operations. | Pilot Programs |

| Robotic Sorting Arms | Robotic arms equipped with sensors for picking and sorting chickens. | Reduction in physical strain on human workers and increased throughput. | In Development |

| Blockchain Tracking | Utilization of blockchain technology for traceability of poultry products. | Enhanced transparency and consumer trust in the supply chain. | Research Phase |

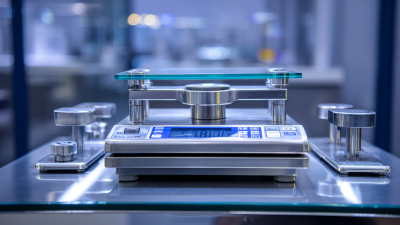

Automated chicken sorting systems are transforming the poultry processing industry by enhancing efficiency, accuracy, and overall productivity. These advanced technologies utilize sophisticated sensors and artificial intelligence to assess various parameters of each chicken, such as weight, size, and quality. By eliminating the need for manual sorting, these systems significantly reduce labor costs and minimize the risk of human error, ensuring that only the best products reach consumers.

The benefits of automated chicken sorting extend beyond cost savings. With the ability to process large volumes of poultry at unparalleled speed, these machines optimize production lines, allowing companies to meet increasing market demands without compromising quality. Furthermore, improved sorting accuracy leads to better product uniformity, which is crucial for consumer satisfaction. The integration of automated systems also facilitates traceability in the supply chain, ensuring that poultry products are safely and reliably sourced. Overall, the future of chicken sorting machines promises a more efficient and quality-conscious industry.

This bar chart illustrates the key benefits of automated chicken sorting systems, highlighting the impressive speed, high accuracy, labor cost savings, and significant reduction in maintenance needs that these technologies bring to poultry processing.

Implementing new sorting machines in poultry processing presents several challenges that can hinder their effectiveness. One significant issue is the high initial investment required for the acquisition and installation of advanced sorting technology. Many processing plants operate on thin margins and may find it difficult to justify the expenditure, especially if the return on investment is uncertain. Additionally, upgrading existing systems to accommodate new machines can disrupt workflow and may lead to temporary production losses.

Another challenge is the integration of these advanced sorting machines with current operations. Workers must be trained to use new technology, which can be a time-consuming process that affects overall productivity. There is also the risk of resistance to change, as employees may be hesitant to adopt new systems or fear job displacement. Furthermore, maintaining the reliability of sophisticated sorting technology in a fast-paced production environment can be difficult, as breakdowns or malfunctions can lead to significant delays and financial losses. Addressing these challenges is crucial for the successful implementation of innovative chicken sorting machines in the poultry industry.

The poultry sorting technology is on the brink of a significant transformation, driven by advancements in automation and artificial intelligence. By 2025, the global food automation market is projected to reach a value of approximately $8.98 billion, with expectations for this figure to rise to $12.2 billion by 2033, reflecting a compound annual growth rate of 3.9%. This growth indicates an increasing demand for efficient and cost-effective solutions within the poultry and broader food industry.

Emerging technologies are revolutionizing the sorting process, enhancing both productivity and precision. AI applications in production and transportation are set to reshape industry standards, making operations not only faster but also more sustainable. Stakeholders in the poultry sector are keenly investing in these innovations, looking for ways to streamline their processes while adapting to evolving market demands.

**Tips:** When exploring new sorting technologies, consider how they integrate with existing systems to minimize disruption. Additionally, prioritize solutions that offer scalability, ensuring your operations can grow alongside market trends. Emphasizing data analytics can also provide deeper insights into performance and areas for improvement.