In the evolving landscape of industrial weighing solutions, the Belt Counterweight Scale stands out as a pivotal innovation poised to enhance accuracy and efficiency across various applications. According to a report by MarketsandMarkets, the global industrial weighing scale market is expected to reach $5.6 billion by 2025, driven by the increasing demand for precise measurement in manufacturing and logistics. As industries seek to improve operational efficiency, Belt Counterweight Scales offer a unique advantage by minimizing errors associated with traditional weighing methods. These scales utilize advanced technology to compensate for fluctuations in belt tension and material properties, resulting in significant improvements in weighing resolution and repeatability. With applications ranging from mining to food processing, the adoption of Belt Counterweight Scales can lead to substantial cost savings and better resource management, marking a significant step forward in the quest for precision in industrial operations.

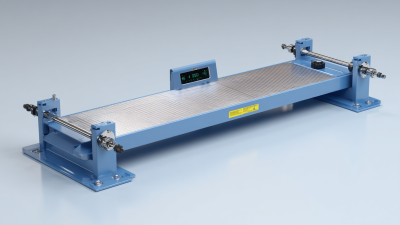

Belt counterweight scales are pivotal in enhancing measurement precision within various industrial applications. These scales function by integrating an accurate weighing mechanism with a conveyor belt system, allowing for continuous monitoring of bulk materials as they are transported. The counterweight system ensures that any variations in the load are promptly compensated, maintaining the required balance and accuracy necessary for effective inventory management and quality control.

Understanding the underlying principles of belt counterweight scales is crucial for their successful implementation. They typically consist of a load cell that detects weight changes, a conveyor belt for material transport, and a counterweight that stabilizes the load. This innovative design aids industries, such as mining, agriculture, and manufacturing, in achieving more reliable data for production monitoring and resource allocation. As advancements in technology continue to emerge, the evolution of these scales promises even greater accuracy and efficiency in industrial processes, ultimately transforming how businesses manage their operations.

In industrial applications, the accuracy of belt counterweight scales plays a crucial role in various processes, from mining to manufacturing. Key factors influencing weighing accuracy include the calibration of the system, the quality of the materials used, and the operational environment. Calibration ensures that the scale correctly measures the weight of materials being transported, while high-quality materials reduce wear and tear, maintaining the scale’s functionality over time.

Tips for ensuring optimal weighing accuracy include regularly monitoring calibration settings and performing routine maintenance checks. Environmental factors, such as temperature and humidity, can also impact scale performance. Therefore, it’s critical to install sensors that mitigate these environmental effects, ensuring consistent data collection.

Another essential factor is the design of the counterweight system itself. An efficient counterweight configuration minimizes errors caused by shifting loads. Maintaining a balanced system is vital, as uneven distribution can lead to inaccuracies. By considering these elements, industries can enhance their weighing accuracy and improve overall operational efficiency.

Innovative technologies are transforming the efficiency and accuracy of belt counterweight scales, which are vital in industrial applications, particularly in sectors like mining and manufacturing. These advancements focus on enhancing measurement precision through improved sensor technologies and data processing capabilities. Modern scales incorporate advanced load cells and digital signal processing, allowing for real-time calibration and adjustments that significantly reduce errors caused by environmental factors and mechanical wear.

Additionally, the integration of IoT (Internet of Things) allows for seamless connectivity and data analytics. This connectivity facilitates remote monitoring and troubleshooting, enabling operators to receive alerts on performance discrepancies and maintenance needs instantly. With predictive analytics, industries can anticipate potential issues before they lead to downtime, further optimizing the operational workflow. As these innovative technologies continue to evolve, belt counterweight scales will play an increasingly crucial role in achieving operational excellence and sustainability in industrial processes.

Implementing belt counterweight scales in industrial settings can significantly enhance precision in weight measurement, which is crucial for optimizing production processes. To achieve this, it is essential to ensure proper installation and calibration of the equipment. Regular maintenance schedules should be established to check for wear and tear, as well as to realign components as necessary. This proactive approach minimizes downtime and maintains accuracy.

Training personnel on the proper operation and troubleshooting of belt counterweight scales is equally important. Providing ongoing education and resources helps staff recognize potential issues early, ensuring responsive action can be taken. Additionally, integrating digital monitoring systems can provide real-time feedback on performance metrics, facilitating immediate adjustments when deviations occur. Adopting these best practices will create a more efficient and reliable weighing system, ultimately benefiting overall production efficacy in industrial applications.

As industries evolve, the demand for precision in weighing systems continues to rise. According to a recent report by MarketsandMarkets, the global market for industrial weighing systems is projected to reach $4.63 billion by 2025, growing at a CAGR of 4.9%. This surge is largely driven by the increasing need for accurate inventory management and quality control in various sectors, including manufacturing, food processing, and logistics. The evolution of belt counterweight scales promises to play a significant role in advancing weighing accuracy, ensuring that industries can optimize productivity while minimizing waste.

Emerging technologies, such as IoT-enabled devices and advanced load cell designs, are reshaping the future of weighing systems. A study from Grand View Research notes that the integration of smart sensors and data analytics is enhancing real-time monitoring capabilities, leading to improved operational efficiencies. These innovations are anticipated to facilitate more precise weight measurements in dynamic environments, which is crucial for applications like bulk material handling and automated production lines. As industrial applications embrace these advancements, the potential for enhanced accuracy and reliability in belt counterweight scales becomes increasingly clear, positioning them as a cornerstone of modern weighing solutions.