Automatic Metal Detectors (AMDs) have evolved significantly since their inception, transforming the way industries approach security, archaeology, and manufacturing. According to a recent report by Markets and Markets, the global market for metal detectors is projected to reach $1.06 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.5% due to increasing safety regulations and technological advancements.

Automatic Metal Detectors (AMDs) have evolved significantly since their inception, transforming the way industries approach security, archaeology, and manufacturing. According to a recent report by Markets and Markets, the global market for metal detectors is projected to reach $1.06 billion by 2025, growing at a compound annual growth rate (CAGR) of 7.5% due to increasing safety regulations and technological advancements.

These devices utilize electromagnetic fields to detect metallic objects, ranging from large tools to small hazardous materials, making them invaluable in various sectors, including mining, construction, and even in airports for security screenings. As the demand for enhanced safety measures continues to rise, understanding the science behind AMDs not only sheds light on their intricate workings but also highlights their critical roles in real-world applications, from safeguarding public spaces to streamlining industrial processes.

Metal detectors operate primarily on the principles of electromagnetism, utilizing alternating currents to create electromagnetic fields. When the current passes through the coil of the detector, it generates a magnetic field that extends into the ground. According to a report by MarketsandMarkets, the metal detector market is projected to reach USD 1.2 billion by 2025, highlighting the growing reliance on this technology for various applications, including security, archaeology, and treasure hunting.

When metal objects are present within the electromagnetic field, they disturb the field and generate their own electromagnetic responses. This interaction is crucial for detection; the metal detector picks up these induced signals, allowing operators to identify the type and location of the metal. The Technical Report by the International Organization of Standards emphasizes that the effectiveness of metal detectors is influenced by factors such as frequency and the type of metal detected. As technology advances, modern detectors increasingly employ Ground Penetrating Radar (GPR) and pulse induction methods, enhancing their accuracy and sensitivity, thus expanding their real-world applications across industries.

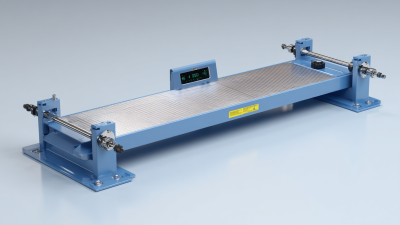

Automatic metal detectors operate based on several key components, each playing a crucial role in their functionality. The most important part is the transmitter coil, which generates an electromagnetic field when powered. This field extends into the ground, and when it encounters metallic objects, it induces eddy currents within them. These currents, in turn, create their own electromagnetic field, which is detected by the receiver coil.

The receiver coil is paired with sophisticated electronics that analyze the signal produced by the detected metal. The phase shift and amplitude of the received signal help determine the type and depth of the metal object. Additionally, most metal detectors are equipped with a control box containing the circuitry and user interface, allowing operators to adjust sensitivity levels and filter out unwanted signals, such as those from mineralized soil or other interference. Together, these components enable effective metal detection, making them invaluable in various applications from treasure hunting to security screening.

In various industries, the need for effective metal detection systems is becoming increasingly crucial. For instance, in the automotive manufacturing sector, the detection and localization of anomalies in sheet metal glue lines are vital for ensuring quality assurance. Recent studies highlight that such capabilities are integral to maintaining high safety and performance standards, particularly as manufacturers strive for precision in their production processes. Advances in unsupervised image anomaly detection models have shown promise in enhancing these detection capabilities.

Moreover, the global pharmaceutical sector is witnessing significant growth in metal detection technology, estimated to reach $157.1 million by 2025, growing at a robust CAGR of 4.7%. This growth underscores the reliance on sophisticated metal detection systems to meet stringent regulatory requirements and ensure product safety. Additionally, the recycling industry is evolving, with innovations such as Hybrid-YOLOv5 improving the detection of non-ferrous metals in end-of-life vehicles, reflecting a shift towards more sustainable practices and efficient resource recovery in manufacturing and waste management. These developments illustrate the diverse real-world applications of metal detection systems, highlighting their crucial role across multiple sectors.

Modern metal detectors have significantly evolved, showcasing impressive effectiveness and accuracy in various applications. Statistical data reveals that contemporary detectors can identify metal objects buried up to several feet underground with an impressive success rate. For instance, studies indicate that high-frequency pulse induction metal detectors boast detection rates of around 90% for small objects, while very low-frequency detectors achieve comparable results for larger items within the same depth range. This extraordinary precision is crucial for professions such as archaeology, security, and construction, where detecting metal artifacts or hazardous materials is paramount.

Furthermore, advancements in technology have led to enhancements in the algorithms used by these devices, resulting in reduced false positive rates. Research indicates that modern metal detectors can distinguish between different types of metals, such as iron and gold, with increased accuracy. This capability not only improves the efficiency of treasure hunting and surveying but also plays a vital role in security settings where distinguishing between harmless metals and potential threats is essential. The statistical effectiveness and accuracy of these devices underscore their importance in both everyday life and specialized fields.

Recent advancements in metal detection technology are paving the way for exciting innovations and diverse applications across various industries. The upcoming 2025 Shenzhen International Touch and Display Expo will showcase the latest developments in sensor technologies, including automatic metal detectors, emphasizing the role of interdisciplinary collaboration in driving industrial upgrades. This event highlights the intersection of sensor technology and metal detection, demonstrating how these innovations can enhance product safety and quality control in manufacturing processes.

As the market for textile metal detectors grows significantly—projected to reach $250 million by 2030 with a compound annual growth rate of 9.5%—the push for smarter, more efficient solutions is accelerating. New technologies are not only improving detection capabilities but also integrating artificial intelligence and machine learning to optimize functionality. These advancements bring possibilities for better risk management in various sectors, from food safety to recycling, marking a crucial step towards a more sustainable and responsive industrial landscape.